Magnetism Myths

Excerpted from American Welding Society, by Damian Kotecki:

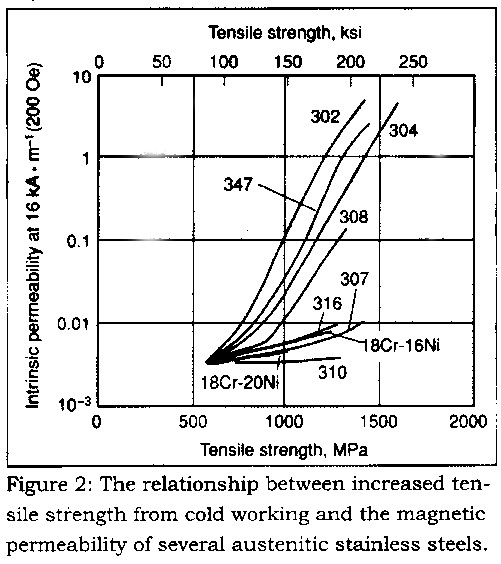

Magnetism Correlation to Tensile Strength / Work Hardening

As Formed, 110,000 Ksi Tensile Footman Loop, After Work Hardening

Footman Loop Heated to 2,000°F, Then Quenched. Dead Soft, Non-Magnetic.

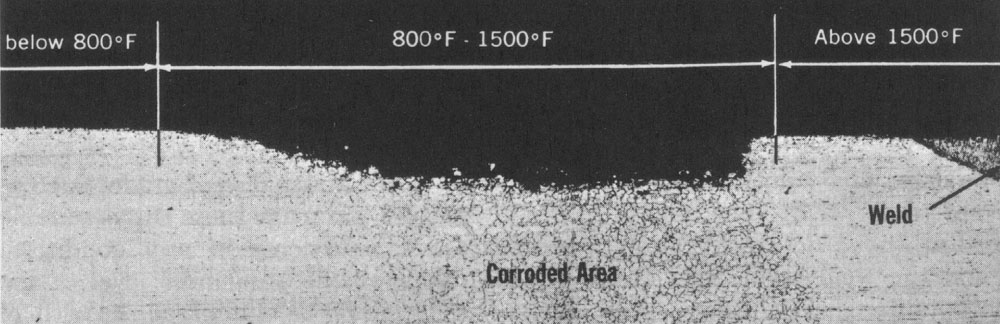

Chromium Carbide Precipitation (Rust!)

Type 304L Stainless Steel is used in all our hardware unless otherwise specified. Typical Breaking loads are calculated on this grade in the fully annealed condition even though the wire will typically be 110,000 to 120,000 PSI. However, the area found at the weld and heat affected zone adjacent to it will be reduced to around 85,000 PSI. Our welding process includes a quick quench, followed by a passivation operation which eliminates any contamination from the surface, leaving a mostly chromium bearing matte-finish. (Remember, SS is still 75% Iron!). The parts are then honed and polished with our own process, which gives the look and shine of polished chrome.

CARBON FIBER SAIL PROBLEMS

We understand there is a problem with rust forming on the rings used on Carbon Fiber Sails. We are looking into this problem and I believe the article and comments below shed a little light on the subject.

We have gotten this feedback:

Damian Kotecki :

"As for rust occurring on the rings, I think you are on to the cause - wet exposure is ok, dry is ok, but salt concentration as occurs while the salt water is evaporating is more aggressive than either wet or dry."

And then -

"Just another thought about the carbon fiber sails - Maybe they are a problem because carbon fiber is electrically conductive, so it may make for an electro-chemical cell???"

We contacted ASM and they referred Jim Fritz from TMR Stainless Consulting to us who offered the following info: Carbon can indeed set up a electrical galvanic corrosion cell with SS. Refineries do not use graphite gaskets in SS pipelines anymore because of the galvanic corrosion that has eaten away at the seals in the past.

Then Dana Seymour, of Doyle Offshore Sails in Barbados Called to discuss rust problems - Actually, a couple instances. The first problem was actually in a Dacron sail, but it turned out that the rusting was coming from pressed in rings which we do not manufacture, so we will leave that discussion there. However, the following observations are very telling -

"I had one observation on the carbon/stainless problem. I have only seen this rusting problem when the s/s ring is what I would call "grounded" to the boat. We discussed on the phone that the clew ring on a Beneteau First class 10, with a carbon /Kevlar mainsail that had rusted. It was shackled to a wire outhaul pulley system in the boom. The Genoa, made of the same material, was untouched (no signs of rust). It was attached by a bowline of spectra/Kevlar rope." "One more thing, is what happens to carbon when it is excited. Say rubbing the fibers together creating fiction or putting it under immense load and then quickly releasing that load (around a winch). This is occurring in the sail regularly. It is also possible that static charges are building up on the surface of all sails but only carbon can move the charge. They build up on aircraft wings why not sails. I don't really understand galvanic reactions but if they involve the movement of electricity this could explain a few things"

In later discussions with other lofts such as UK, their construction uses a layer of sticky back fabric over that portion of the ring that would otherwise come in contact with the sail, thereby isolating the metal from the conductive carbon. This has eliminated any further electrolysis and seems to have the problem under control.

Nirtonic 50

This material is well known for it's role in standing rigging. We are In the process of testing this material in the field. It's tensile strength is 50% above that of 304/316, the yield is nearly double, with the corrosion resistance of Monel. Preliminary shop tests with a 5/16" ring show break loads at 19,600#, compared to 13,500# for comparable 304 SS ring. This should enable reduced ring size, thereby reducing weight. Plans are to have them done in Black Oxide, Identifying them from other rings and blending in with the carbon fiber. These added benefits should offset the additional cost.

CORROSION

(The following is an excerpt from Brion Toss’s book “The Complete Rigger’s Apprentice – Tools and Techniques for Modern and Traditional Rigging” (International Marine; Camden, Maine 1998).)

"Corrosion is always a problem in a saltwater environment, particularly when you mix antagonistic materials such as aluminum and stainless or stainless and carbon fiber; these materials are on different points on the galvanic scale, and when joined by the conductive medium of salt water they set up an electrical potential. The resulting activity corrodes whichever of the two materials is least noble (lower on the galvanic scale). While not as serious with rigging as with permanently immersed items such as hull fastenings, galvanic corrosion can over time weaken aluminum and carbon fiber spars and clog such machinery as winches and blocks.

"The first thing to do is to take note of places where dissimilar materials are in contact. Then go about isolating them with some form of nonconductive bedding. This can be as low-tech as parceling and serving to isolate galvanized steel wire from bronze thimbles, or it may involve 3M 101, Alumelast, or other polyurethane or plastic compounds to isolate aluminum or stainless fasteners. When surveying an aluminum spar, pull a few fasteners and examine the screws and the holes they came from. If you see a white powdery substance on either, you’ve got galvanic corrosion. If the fasteners shear off when you try to pull them, you’ve got serious galvanic corrosion. The most likely places for galvanic corrosion to occur are at the mast step, under sail tracts, and under winches.

"Stainless steel, the dominant material in rigging today, is susceptible to its own special form of decay: crevice corrosion, also known as oxygen starvation. Stainless steel contains significant amounts of chromium. When exposed to the atmosphere the surface oxidizes slightly and a thin film of chromium oxide forms, preventing any further oxidation. If exposed to water, salt or fresh, without the presence of air, this film will not form and the metal will corrode. If the water in question is salt water, the process is accelerated.

"You risk oxygen starvation anytime you cover stainless, as when applying spreader boots, shroud rollers, or service. (OR WEBBING!) The trick is to exclude both water and air. When serving, some anhydrous lanolin covered with proper parceling and service works fine. Lanolin or mineral oil under shroud rollers is also good. Just rinsing stainless with fresh water whenever you can will lessen the corrosive effects of salt water.

"When surveying for stainless corrosion, don’t be distracted by stains. Contrary to what the name implies, the stuff does stain, mostly from bits of mild steel scraped off the extruding dies when the wire is formed. But do look closely, preferably with a magnifying glass, for any sign of pitting in the metal – the surface will seem to have teeny-tiny craters in it. Any significant pitting is cause for replacement. When in doubt, proof-test, running the wire up to 50 percent of its rated strength on a testing machine. If nothing breaks, it was a relatively cheap way to check. If it breaks, you’ll feel very prudent for checking. Proof-testing is a good idea after five to ten years in northern climates, or three to five in the tropics, even without evidence of pitting, just to make sure the wire hasn’t fatigued or suffered other damage. (Bo'sun Note: We usually recommend to customers that they seriously consider replacement of the rigging within these timeframes. Proof-testing is not always possible or practical. Better to be safe than sorry!)

"Just how frayed, rusty, or old, or whatever, must a piece be for it to be condemned? There are plenty of people out there who can point to a battered but still-functioning wreck and tell you that it’s held up fine and they’d still trust it in a gale. Gear will sometimes hold together far longer than anyone could reasonably expect. But the point is to have, not a long-lived rig, but a safe long-lived rig. Why incorporate a safety factor in a rig design, only to erode it away? In view of the possible consequences of gear failure, it seems foolhardy to go out with anything but the strongest, best-conditioned rig that is compatible with performance and your purse. Watch, understand, and respond as if it were an instinctive feeling of your inner self.

"Sometimes metal just plain rusts. Stainless steel rusts more slowly, but tropical climates will get to it in just a few years. Galvanized steel left untended can dissolve in a matter of months. Any survey of metal must be a survey for rust. ..."

For more information on Corrosion data, including Stress Corrosion Cracking, Crevice Corrosion, Pitting, etc, check out:

|

ROUND RING TENSILE TESTS

RING SIZE | 10% ID | 25% ID | ULTIMATE LOAD | END RESULT |

3/16" X 1" (RR1810) 4.76 X 25.4 MM | 1,525 # 692 Kg | 2,900 # 1315 Kg | 4,500 # 2,041 Kg | NYLON TUBULAR WEBBING - WEBBING RUPTURES (2 LAYERS AROUND RING, 3 LAYERS AROUND SHACKLE) |

3/16" X 1 1/4" (RR1812) 4.76 X 31.75 MM | 1,770 # 803 Kg | 4,880 # 2,214 Kg | NYLON TUBULAR WEBBING - RING BREAKS IN WELD, 3 LAYERS AROUND RING, 2 LAYERS AROUND SHACKLE. | |

1/4" X 1" (RR2510) 6.35 X 24.4 MM | 3,600 # 1,633 Kg | 7,500 # 3,402 Kg | 8,650 # 3,924 Kg | SPECTRA WEBBING - RING BREAKS, HAZ. 4 LAYERS WEBBING AROUND RING, 3 AROUND SHACKLE |

1/4" X 1 1/4" (RR2512) 6.35 X 31.75 MM | 2,600 # 1,179 Kg | 4,200 # 1,905 Kg | 7,000 # 3,175 Kg | NYLON TUBULAR WEBBING - STITCHING TEARS ON WEBBING - ZIPPER EFFECT 3 LAYERS AROUND RING, 2 ON SHACKLE |

1/4" X 1 1/2" (RR2515) 6.35 X 38.1 MM | 2,000 # 907 Kg | 3,020 # 1,370 Kg | 8,920 # 4,046 Kg | SPECTRA WEBBING - RING BREAKS, HAZ. 4 LAYERS AROUND RING, 3 AROUND SHACKLE |

5/16" X 1 1/4" (RR3112) 7.93 X 31.75 MM | 4,840 # 2,195 Kg | 7,600 # 3,447 Kg | 12,500 # 5,670 Kg | SPECTRA WEBBING - RING BREAKS IN WELD. 4 LAYERS WEBBING AROUND RING, 3 AROUND SHACKLE |

5/16" X 1 1/2" (RR3115) 7.93 X 38.1 MM | 3,840 # 1,742 Kg | 5,950 # 2,700 Kg | 11,800 # 5,352 Kg | SPECTRA WEBBING - STITCHING PULLS OUT. 4 LAYERS ON RING, 3 LAYERS AROUND SHACKLE. |

5/16" X 1 3/4" (RR3117) 7.93 X 44.45 MM | 3,240 # 1,460 Kg | 5,100 # 2,313 Kg | 11,860 # 5,380 Kg | SPECTRA WEBBING - STITCHING PULLS OUT. 4 LAYERS AROUND RING, 3 LAYERS AROUND SHACKLE. |

5/16" X 2" (RR3120) 7.93 X 50.8 MM | 2,450 # 1,111 Kg | 3,890 # 1,765 Kg | 8,400 # 3,810 Kg | NYLON TUBULAR WEBBING - STITCHING BEGINS TO PULL OUT ON ENDS, THEN RUPTURES. 4 LAYERS AROUND RING, 3 ON SHACKLE. |

3/8" X 1 1/2" (RR3715) 9.52 X 38.1 MM | 5,500 # 2,495 Kg | 8,500 # 3,855 Kg | 14,160 # 6,423 Kg | SPECTRA WEBBING - STITCHING PULLS OUT. 4 LAYERS AROUND RING, 3 AROUND SHACKLE. |

3/8" X 1 3/4" (RR3117) 9.52 X 44.45 | 4,850 # 2,100 Kg | 7,520 # 3,411 Kg | 13,910 # 6,310 Kg | SPECTRA WEBBING - STITCHING PULLS OUT. 4 LAYERS AROUND RING, 3 AROUND SHACKLE. |

7/16" X 2" (RR4120) 11.11 X 50.8 MM | 7,460 # 3,384 Kg | 9,200 # 4,173 Kg | 15,210 # 6,900 Kg | SPECTRA WEBBING - STITCHING (SEWN AROUND CIRCUM. ALSO) RIPS OUT (EXPLODES). 4 LAYERS ON RING, 3 ON SHACKLE |

1/2" X 2 1/2" W/BAR 12.7 X 63.5 MM (RR5025WB) | N/A | N/A | N/A | SPECTRA WEBBING - STITCHING PULLS OUT AT 15,500 # BEFORE ANY APPRECIABLE DEFORMATION. 5 LAYERS ON RING, 4 LAYERS ON SHACKLE. |

RR3715@ 8500#, 10% Reduction RR3717 @ 7520#, 25% Reduction

OBSERVATIONS:

Obviously, the Spectra webbing is far superior to the nylon webbing. Not only does it appear to be more abrasion resistant, when is sewn thoroughly it does, for the most part, eliminate the `Zipper Effect' which plagues the Nylon webbing. In this series of tests, the only incidence of failure in the spectra fabric was in the 7/16" x 2" test. In this instance, the edges were sewn on the circumference in addition to the regular stitching. This seemed to eliminate the failure starting at the ends. Instead, an inside layer snapped at the same time the stitching failed, resulting in an instant, explosive failure. Also, in the smaller rings which were pulled with the nylon webbing, having the 3 layered side around the ring could make the difference between torn webbing at lower loads, or a broken ring at a higher ultimate yield.

CLEW RING TENSILE TESTS

RING SIZE | 1ST INSPECTION | 2ND INSPECTION | 3RD INSPECTION | FINAL RESULT |

BD3120, 5/16" X 2" 7.93MM X 50.8MM | 4,500# NO APPARENT DISTORTION | 10,500# - WEBBING BREAKS ONE SIDE | ONLY TWO WEBBING STRAPS - RING IS FAIRLY DISTORTED, BUT NOT TERRIBLY | |

BD3726, 3/8" X 2 5/8" 9.5MM X 66.7 | 4,300# CENTER BAR STARTS TO BEND | 9,000# QUITE DEFORMED - CENTER BAR BENDING UP* | 15,600# WEBBING BREAKS IN ONE EAR | *3 STRAPS - STRAP AROUND CENTER BAR SEEMS TO CAUSE EXCESS DEFORMATION |

BD4130, 7/16" X 3" 11.1MM X 76MM | 9,000# BOTTOM AND CENTER BAR BEND | 13,000# MODERATELY DEFORMED BOTH WAYS | 19,200# STITCHING ON RIGHT EAR PULLS OUT | 3 STRAPS USED AT ALL TIMES - CAUSES CROSSBAR TO DISTORT |

BD5037, ½ " X 3¾" 12.7MM X 95.3MM | 9,000# BOTTOM OF RING DEFORMS SLIGHTLY (ONLY 2 STRAPS USED) | 14,000# BOTTOM OF RING DEFORMS CONSIDERABLY (ONLY 2 STRAPS USED) | 19,000# RIGHT STRAP BREAKS - WELD BEGINS TO TEAR IN MIDDLE (W / CENTER STRAP USED) | 3 STRAPS - CENTER STRAP AROUND BAR USED ONLY IN FINAL PART OF PULL |

DD3120, 2" X 5/16" 7.93MM X 50.8MM | 4,000# NO APPARENT DISTORTION | 6,000# SOME DISTORTION CENTER WEB SLIDES ALL THE WAY TO LEFT | 12,700# LEFT WEB BREAKS - CENTER WEB BEGINS TO TEAR | 3 STRAPS - WHEN CENTER WEB SLIPS TO SIDE, CENTER BAR IS SLIGHTLY DISTORTED UPON ONE SIDE |

DD3726, 3/8 X 25/8" 9.5MM X 66.7MM | 4,300# NO APPARENT DISTORTION | 6,000# BOTTOM STARTS TO DEFORM | 17,100# WEBBING BREAKS ON ONE SIDE - CENTER BAR PULLS UP AND OUT | 3 STRAPS - CENTER STRAP PULLS CROSS BAR OUT, WEAKENING IT'S STIFFENING INTENT |

DD4130, 7/16" X 3" 11.1MM X 76MM | 9,000# BARLEY DISCERNABLE DISTORTION ON BOTTOM | 13,000# BOTTOM SLIGHTLY DEFORMED | 14,500# ONE STRAP BREAKS - VERY LITTLE DISTORTION | ONLY TWO WEBBING STRAPS USED IN EYES - ONE STRAP BREAKS |

BD4130, 7/16" X 3" 11.1MM X 76MM | 9,000# BOTTOM SLIGHTLY MORE DEFORMED THAN WITH ONLY 2 STRAP | 13,000# CENTER STRAP SLIPS TO LEFT- BOTTOM BADLY DEFORMED | 20,900# RIGHT EAR WEBBING BREAKS | 3 STRAPS - CENTER STRAP SLIPS TO ONE SIDE - BOTTOM DEFORMS BADLY |